Materials we need

To prepare the banana chips we need the following materials:-

Raw banana (Nendran), oil, salt, spices, Gas, Knives, small fruit slicer or hand slicer, Plastic buckets, bowls, Polythene bags, brand labels and Bag sealer.

|

| Hand slicer |

Selection of raw material and purchasing of bananas from wholesalers

Nendran, a variety of banana growing in some parts of South India is the most suitable variety for making chips. Traditionally, raw Nendran bananas are essential to use under-ripe green bananas as these have the correct texture for drying and frying. If plantain is used, select nearly ripe fruit that has stiff and starchy flesh. Ripe and over ripe bananas and plantains should not be used as the texture is too soft to make the chips.

Preparation of raw material

Bananas should be peeled just before they are used because when the flesh is exposed to the air it turns brown. This does not affect the eating quality but it does not look very attractive. Peeled bananas can be prevented from turning brown by brushing them with a solution of ascorbic acid (vitamin C) or the juice from lemon, lime or orange. Alternatively, the peeled banana slices can be soaked in a solution of citric acid (made by mixing 1 part lemon juice with 2-3 parts water) for 3-5 minutes. Do not leave the slices in the water for longer than this as they become too wet and soft and will take longer to dry. Remove the slices from the water and allow to drain.

Slice the bananas crosswise or diagonally crosswise for the smaller bananas into slices that are about 1-2 mm thick. Try to ensure that all pieces are the same thickness so that they all dry and fry at the same rate. A packet of banana chips of varying thicknesses is less attractive than one in which the pieces are of uniform thickness. You can use a small kitchen slicer to ensure that the pieces are of uniform thickness. However, for Nendran chips do not make very thin or thick slices. Pre-treat the slices with acidified water, a solution of ascorbic acid, a fruit juice dip or a honey dip to prevent them from browning.

Chips preparation process:-

There are two different methods for making banana chips. One of these is to deep fry thin slices of banana in hot oil, in the same way as potato chips or crisps. Traditionally, coconut oil is used for deep-frying the Nendran chips, which will give a pleasant aroma while eating.

The other is to dry slices of banana, either in the sun or using a solar or artificial dryer. The products made by the two methods are quite different. The deep fried chips tend to be a savoury, high calorie product that is eaten as a snack food. Because they are deep fried in oil they have a fairly short shelf life- up to 2 months maximum when stored in the correct conditions. The oil is prone to turning rancid and the crisps to becoming soft if they are not stored in air-tight containers. The dried chips are a more ‘wholesome’ product. They too are eaten as a snack food and are often added to cereal mixes such as muesli. The chips can be dried without any additives or they can be coated with a syrup or honey dip prior to drying which gives a sweeter tasting, higher calorie and possibly more attractive looking product. Chips made by drying have a longer shelf life (up to 6 months) as long as they are dried to a low moisture content and stored in a cool dry place. Bananas can also be dried whole or in long strips until they are leathery and chewy. They have a higher sugar content and are not crispy like the dried chips. They are sometimes referred to as banana figs. This brief explains how to make fried banana and plantain chips and dried banana chips.

Fried banana chips Principles of preservation Under-ripe mature banana or plantain is cut into thin slices and fried to a crisp texture. The slices can be partially dried before frying which removes some of the moisture and makes them more crispy. Frying removes some of the water, gelatinizes the starch, destroys enzymes and micro-organisms and gives a crisp product with a characteristic aroma and taste.

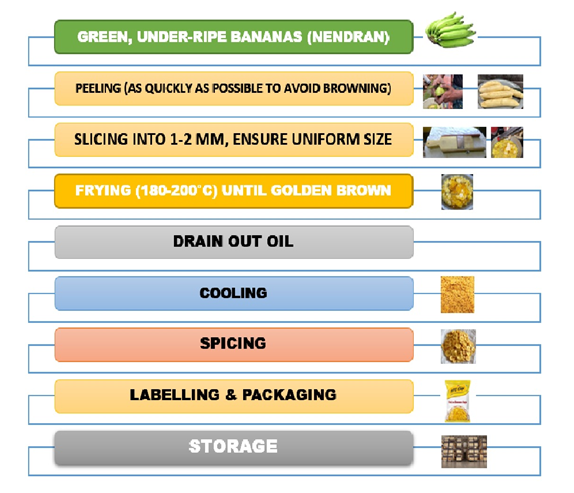

FRIED BANANA CHIPS – PROCESS FLOW-CHART

Quality Control :-

After drying and cool to room temperature. All the products needs to be thoroughly checked by quality control team. Finally, passed products are only now eligible and ready for moisture-proof packaging.

Packaging and labeling of product :-

You may your moisture-proof packing are being done through manual or automation project. Labeling including all product information i.e. date of manufacturing, product expiry date, calorie details with company logo should be pre-printed in bio-degradable packets.

Storage :-

On completion of individual packaging, these should be shifted into medium range cartoons (one cartoons containing 48 individual packets) and also the cartoons may be stored in warehouses.

Tagline :-

Best quality is our moto

Grading and standardization :-

The 'xxx Chips Company” to be registered with Ministry of Micro, Small & Medium Enterprises (MSME) and should also be registered with Food Safety and Standards Authority of the country (As per your country policies).

Channels of distribution

Further the final products may distributes all over the country, also you may export the products to other countries.

Comments

Post a Comment